🔍 Lean vs. Six Sigma: What’s the Difference—and Why Use Both?

In the world of Operational Excellence, Lean and Six Sigma are often mentioned together—but they are not the same. Each methodology brings unique strengths to the table, and when combined, they create a powerful framework for driving sustainable improvement.

What Is Lean?

Lean focuses on eliminating waste and improving flow. Originating from the Toyota Production System, Lean emphasizes:

Value from the customer’s perspective

Continuous improvement (Kaizen)

Standardized work

Visual management

Empowering frontline teams

Lean tools like 5S, Value Stream Mapping, and Kanban help organizations streamline processes and reduce non-value-added activities.

✅ Lean focuses on eliminating non-value-added activities and improving process flow.

What Is Six Sigma?

Six Sigma is a data-driven methodology aimed at reducing variation and improving quality. It uses statistical tools and the DMAIC framework:

Define

Measure

Analyze

Improve

Control

Six Sigma projects often require deeper analysis, root cause identification, and measurable results. It’s especially effective in complex processes where defects or errors are costly.

✅ Six Sigma targets reducing variation and enhancing quality.

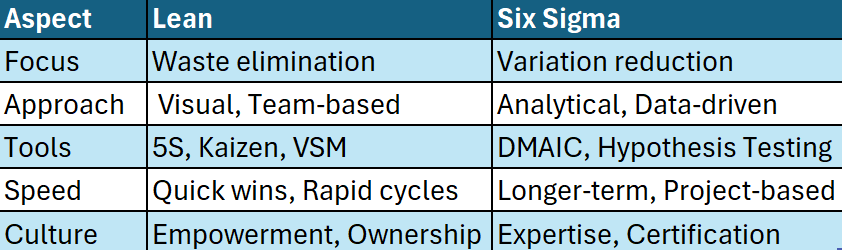

Key Differences

How They Complement Each Other

Lean and Six Sigma are not competing philosophies—they’re complementary. Lean improves speed and flow, while Six Sigma ensures consistency and quality. Together, they:

Accelerate problem-solving with both quick wins and deep dives

Engage teams at all levels—from frontline to leadership

Drive measurable results in cost, quality, and customer satisfaction

Build a culture of continuous improvement with structure and flexibility

Bringing It All Together in Operational Excellence

In practice, combining Lean and Six Sigma allows organizations to tackle a wide range of challenges. For example:

A Lean approach might identify bottlenecks in a process.

A Six Sigma project could then analyze the root causes of those delays.

Together, they deliver a solution that’s both efficient and statistically sound.

By leveraging the strengths of both, Operational Excellence professionals can create systems that are not only faster and cheaper—but also more reliable and resilient.